- About us

- Products

Blood Bank Equipments

- Blood Bank Refrigerator

- Plasma Freezer (-40°C)

- Ultra Plasma Freezer (-80°C)

- Platelet Incubator (22°C)

- Platelet Agitator

- Cryo Bath (4°C)

- Thawing Bath (37°C)

- Tube Sealer

- Blood Collection Monitor

- Plasma Extractor

- Tube Stripper

- Blood Bank Centrifuge

- Laboratory Centrifuge

- Donor Couch

- Laminar Air Flow

- Weighing Scale

- VDRL Shaker

- Laboratory Oven

- Incubator

- Water Bath

PHARMA EQUIPMENTS

- Stability Chamber

- Photo Stability Chamber

- Walk-In Stability

- BOD Incubator

- Hot-Air-Oven

- Vaccum Oven

- Bio Safety Cabinet Class II Type A2

- Bio Safety Cabinet Class II Type B2

- Pass Box Dynamic

- Pass Box Static

- Reverse Laminar

- Air Shower

- Refrigerator (2°C to 8°C)

- Cold Room Chamber

- Freezer (-40°C)

- Ultra Freezer (-80°C)

- Infrastructure

- Gallery

- Media

- Contact us

Bio Safety Cabinet Class II Type B2

A Class II Type B2 biosafety cabinet is designed to provide an extra layer of protection for laboratory personnel working with biological materials that may pose a moderate risk to human health or the environment. It offers a higher level of protection than a Class II Type A2 biosafety cabinet.

The Class II Type B2 BSC utilizes a HEPA/ULPA filter to create a negative pressure environment that prevents any contaminants from being released into the laboratory. This type of cabinet also features an air exhaust system that removes potentially harmful substances from the environment, providing an additional layer of protection for laboratory personnel.

Class II Type B2 biosafety cabinets are equipped with several features designed to enhance usability and convenience. For example, some models have an adjustable height work surface that can be tailored to the specific needs of laboratory personnel. Additionally, they may include built-in lighting to provide clear visibility during procedures.

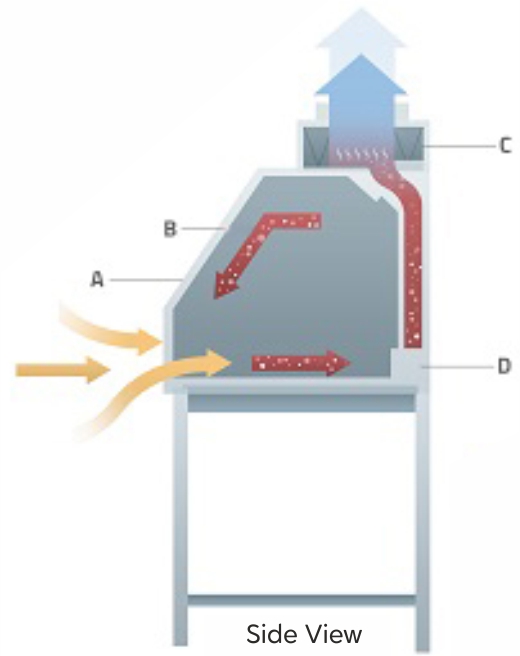

BIO-SAFETY CABINET: CLASS II TYPE B2 FLOW DIAGRAM

- Ambient air is pulled through the front grille to prevent contamination of the work surface and work product. The inflow does not mix with the clean air within the cabinet work zone.

- Ambient air is taken in through a pre-filter at the top of the cabinet, and passes through the downflow HEPA / ULPA filter, entering the work zone as laminar flow. The uniform, non-turbulent air stream protects against cross contamination within and throughout the work area.

- Near the work surface, the downflow air stream splits with a portion moving toward the front air grille, and the remainder moving to the rear air grille. A small portion of the HEPA / ULPA filtered downflow enters the intake perforations at the side capture zones at a higher velocity (small blue arrows).

- A combination of inflow and downflow air streams forms an air barrier that prevents contaminated room or from entering the work zone, and prevents work surface emissions from escaping the work zone. The downflow combined with the inflow air enters the common air plenum.

- All air in the common plenum is HEPA-filtered and exhausted via a dedicated ducting system to the external environment.